Introduction

Anyone responsible for the efficiency for an organization that develops software, executes devops, or operates IT is faced with many hard questions:

- Do you have visibility into the performance of your teams?

- How do you identify the sources of delay in your process?

- How do you identify bottlenecks? optimize assignments?

- Can your teams detect the need for — and implement — improvement?

The means to answer these questions have emerged over the last few years:

- The adaptation of lean techniques, born in manufacturing, to software

- The ready availability of process execution data and data analysis tools

Many organizations have realized significant performance improvement with the adoption of agile methods. Agile offers genuine advantages for most, if not all, organizations. However, adopting agile alone may result in:

- Less than optimal collaboration between the teams and management in optimizing throughput and minimizing cost of delay.

- Difficult budget conversations with stakeholders such as the CFO who wants to know if their your teams are efficient, competitive with outsourcing opportunities, money is being spent wisely.

Other organizations, for a variety of reasons, have not adopted agile or have found it inappropriate for their organization, but still require a systematic way of implementing continuous improvement.

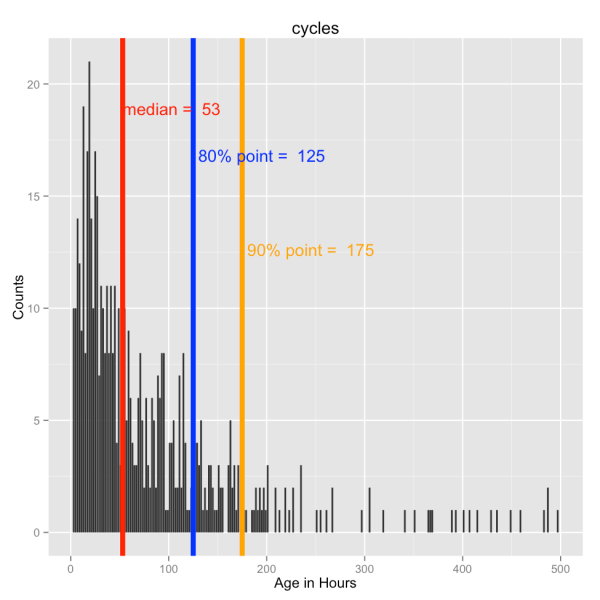

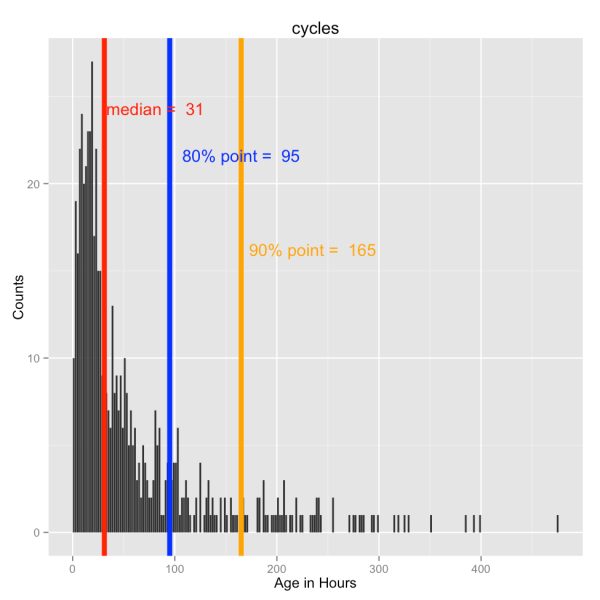

For these and other reasons, there is a growing trend towards adapting lean principles and practices to software development, chief among them Kanban. However, fully applying and realizing the benefits of lean to software, devops, and IT, and scaling to medium and large projects, one needs to take a systematic approach to adopting lean. Moving beyond platitudes, modern lean is based on instrumenting the process so one can apply the lean product flow insights laid out by Don Rienertsen To instrument the process and apply the following practices: Modern lean, as a broad set of principles and techniques, applies to whatever process your organization follows. Applying the approach starts with a survey of the process work products. Some of these are deliverables such as code modules, releases, and documentation. Others are process-related such as architecture specifications, feature requests, and work items. The key artifacts are studied more deeply with work-product tailored value stream maps. More detail on this may be found in the Cutter Consortium Executive Report “Implementing Product Flow Measures for Software and DevOps”. The value streams are used to discover and prioritize process-improvement opportunities by raising such questions as As described in the Report, with the identification of the core work products one is in a position to instrument the process and automate the collection of the data to surface the lean measures. With these measures, the team has the information they need to optimize the flow by detecting bottlenecks, sources of delays, and trends in throughput. For just one example, consider figures 1 and 2 below. These as histograms of the time (in hours) it took to for a set of work products to flow through the process. The horizontal axis is the number of hours, and the vertical axis is the number of items that took that number of hours. Note the shape of the histograms with the long tails is typical for real customer data. Figure 1 shows the performance of the team before using the value streams or applying the flow principles. As you can see, it took 125 hours to complete 80% of the work products. The team identified and implemented opportunities for improvement resulting in the histogram in Figure 2. Figure 2 shows what improvement looks like. The shape of the histogram is the same but is weighted much more to the left – more items took less time. In this case, it took only 95 hours to complete 80% of the items. In fact, one could track the trend of the team’s performance by tracking the 80% over time. Figure 1. Initial Histogram of Cycle Times Figure 2. The Histogram after taking some improvement actions. With our approach to lean, you will have the tools and information you need not only to answer the questions, but also to take informed action to With tailored lean, by focusing on the work to be done, enabling and empowering the staff to do their work, everyone wins. The team feels their time is spent doing useful work and morale improves. Since software and IT are central to the entire world economy, Development and IT organizations vary widely. They differ in It follows that there is no royal road to lean. To help you get on the right path, we offer This initial assessment will result in a plan to put you on the path to a successful lean deployment. The assessment will cover Deliverables from the assessment include: After an initial discussion with the key stakeholders, we will tailor and deliver a 3 or 4-day course on adopting lean for development and IT. Our course is not restricted to the lean culture discussion, but is focused on the key practices for applying lean to development, IT, and DevOps. The topics include: This service is available with or without the assessment. This is a tailored engagement based on the results of the assessment. It will consist of planning and the concrete delivery of a measurement and analytics systems. Depending on your needs and initial capabilities, we will work with your staff to: [1] Donald Reinertsen, The Principles of Product Development Flow: Second Generation Lean Product Development, Celeritas Publishing, May 8, 2014Lean software assessment and rollout service